- Federico Ellade Peruzzotti

- KNF

- 31 likes

- 3414 views

LABORATORY VACUUM DIAPHRAGM PUMPS

Complete guide to choosing your new KNF pump

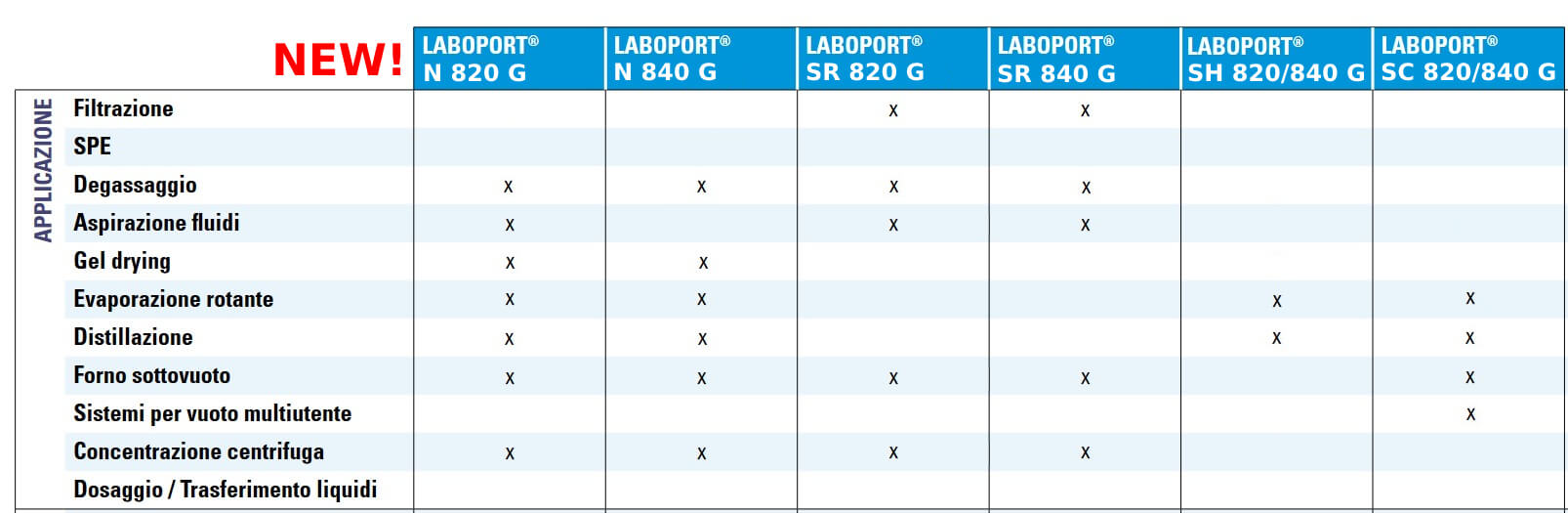

FOR EVERY APPLICATION, ITS LABORATORY PUMP

Follow the list of applications and find the most suitable pump for you.At the bottom you will find summary tables or, if you prefer, download the KNF applications brochure.

DEGASSING

Degassing is the process that leads to the removal of gases dissolved in liquids. Also called degassing, it plays an essential role in applications where the presence of gas in the liquid would be harmful. Degassing is also important for the research and production of resins, gels, plastics and cosmetic creams.

Vacuum degassing is one of the most common and effective methods. Given Henry's law, using a vacuum pump to lower the pressure above the liquid allows dissolved gases to escape more easily.

A vacuum degasser consists of two components: a vessel that holds the liquid and a vacuum pump that controls the pressure in the vessel.

The ideal pump for degassing must:

- operate oil-free with excellent chemical compatibility

- have an adequate flow rate in proportion to the volume of the container

- process humid vapors

- the maximum vacuum depth

The pumps available:

→ Laboport N 820 G - Flow rate 20 l/min, max vacuum 6 mbar and IP30

→ Laboport N 840 G - Flow rate 34 l/min, max vacuum 6 mbar and IP30

→ Laboport SR 820 G - Flow rate 20 l / min, max vacuum 6 mbar and IP30

→ Laboport SR 840 G - Flow rate 34 l / min, max vacuum 6 mbar and IP30

→ Laboport N 816.1.2 KT.18 - flow rate 30 l/min, final vacuum 160 mbar and IP20

→ N 920 KT.29.18 G - flow rate 21 l/min, max vacuum 2 mbar and IP20

→ Laboport N 820.3 FT.18 - flow rate 20 l / min, final vacuum 8 mbar and IP44

CENTRIFUGAL CONCENTRATION

Centrifuges for this application use a combination of centrifugal force, vacuum and heat to quickly and gently evaporate smaller samples into a dry or wet pellet state.

There are many different applications for centrifugal evaporation, including polynucleotide concentration and protein samples, residue analysis, solvent / water mixture concentration, toxicology and forensics, combinatorial chemistry, and food / environmental analysis. Given the nature of the solvents used, a pump with high chemical resistance and good tolerance to condensates is recommended.

The ideal pump should have:

- a sensitive vacuum control

- oil-free operation with excellent chemical compatibility

- ability to process humid vapors

The pumps available:

→ Laboport N 820 G - Flow rate 20 l/min, max vacuum 6 mbar and IP30

→ Laboport N 840 G - Flow rate 34 l/min, max vacuum 6 mbar and IP30

→ Laboport SR 820 G - Flow rate 20 l / min, max vacuum 6 mbar and IP30

→ Laboport SR 840 G - Flow rate 34 l / min, max vacuum 6 mbar and IP30

→ N 920 KT.29.18 G - flow rate 21 l/min, max vacuum 2 mbar and IP20

→ Laboport N 842.3 KT.18 - Flow rate 34 l/min, max vacuum 2 mbar and IP44

→ Laboport N 840.3 FT.40.18 - flow rate 34 l / min and final vacuum 10 mbar

→ Laboport N 860.3 FT.40.18 - flow rate 60 l / min and final vacuum 4 mbar

→ Laboport N 840.3 FT.18 - flow rate 34 l / min, final vacuum 8 mbar and IP44

DISTILLATION

Distillation is a technique used to separate two or more substances of a mixture, exploiting their difference in boiling points, that is, the different volatility.

The high temperature required to distill a compound could damage it, so in some cases the vacuum distillation process is preferred. By lowering the pressure you can also lower the temperature necessary for the process, making the distillation more delicate.

The distillation process is carried out with a laboratory vacuum distillation equipment and the associated vacuum pump.

The ideal pump for distillation must:

- operate oil-free with excellent chemical compatibility

- process humid vapors

- Maximum vacuum depth

- have a flow rate proportional to the volume of the system

- solvent recovery options in both inlet and outlet

- an adjustable control of the vacuum levels

The pumps available:

→ N 86 KT.18 - Small, economical and suitable for almost all uses; flow rate 5,5 l/min and final vacuum 160 mbar

→ Laboport N 820 G - Flow rate 20 l/min, max vacuum 6 mbar and IP30

→ Laboport N 840 G - Flow rate 34 l/min, max vacuum 6 mbar and IP30

→ N 920 KT.29.18 G - flow rate 21 l/min, max vacuum 2 mbar and IP20

→ Laboport N 842.3 KT.18 - Flow rate 34 l/min, max vacuum 2 mbar and IP44

→ Laboport N 860.3 FT.40.18 - flow rate 60 l / min and final vacuum 4 mbar

→ New! Laboport SH 820 G - Flow rate 20 l / min, max vacuum 6 mbar and IP30

→ New! Laboport SH 840 G - Flow rate 34 l / min, max vacuum 6 mbar and IP30

→ New! Laboport SC 820 G - Flow rate 20 l / min, max vacuum 6 mbar and IP30

→ New! Laboport SC 840 G - Flow rate 34 l / min, max vacuum 6 mbar and IP30

.jpg)

ROTATING EVAPORATION

Rotary evaporation is a gentle and energy-saving method for separating and purifying liquids. Using a rotary evaporator has multiple advantages. In fact, thanks to the connected vacuum pump, evaporation will occur faster and, in some cases, safeguarding the properties of the liquid, since the created depression allows a lowering of the boiling temperature of the solvent. Subsequently, a cooling condenser (dry ice or recirculating) will allow the recovery of the separated solvent.

This operation is used for concentration of solutions and suspensions; crystallization or recrystallization; distillation and recycling of solvents; chemical synthesis.

The system is practically divided into two main parts: a rotary evaporator and a vacuum pump.

Considerations for choosing the optimal vacuum pump include:

- oil-free operation with excellent chemical compatibility

- ability to process humid vapors

- maximum vacuum depth

- flow rate proportional to the volume of the system

- solvent recovery options in both inlet and outlet

- adjustable control of vacuum levels

The pumps available:

→ Laboport N 820.3 FT.18 - flow rate 20 l / min, final vacuum 8 mbar and IP44

→ Laboport N 840.3 FT.18 - flow rate 34 l/min, final vacuum 8 mbar and IP44

→ Laboport N 820 G - Flow rate 20 l/min, max vacuum 6 mbar and IP30

→ Laboport N 840 G - Flow rate 34 l/min, max vacuum 6 mbar and IP30

→ N 920 KT.29.18 G - flow rate 21 l/min, max vacuum 2 mbar and IP20

→ Laboport N 842.3 KT.18 - Flow rate 34 l/min, max vacuum 2 mbar and IP44

→ Laboport N 820.3 FT.40.18 - flow rate 20 l / min and final vacuum 10 mbar

→ Laboport N 840.3 FT.40.18 - flow rate 34 l / min and final vacuum 10 mbar

→ Laboport N 860.3 FT.40.18 - flow rate 60 l / min and final vacuum 4 mbar

→ New! Laboport SH 820 G - Flow rate 20 l / min, max vacuum 6 mbar and IP30

→ New! Laboport SH 840 G - Flow rate 34 l / min, max vacuum 6 mbar and IP30

→ New! Laboport SC 820 G - Flow rate 20 l / min, max vacuum 6 mbar and IP30

→ New! Laboport SC 840 G - Flow rate 34 l / min, max vacuum 6 mbar and IP30

FILTRATION AND SEPARATION OF THE SOLID PHASE

Contrary to simple gravimetric filtration, the use of a vacuum pump will allow you to more effectively suck the fluid through the filter.

Care must be taken to match the pump to the application, as insufficient vacuum will prolong the process while excessive vacuum can collapse or tear the filter paper. A simple solution to manage the vacuum level is to equip the pump with a vacuum regulator and a pressure gauge.

Pump selection is influenced by various factors, including filter size, number of filters (if using a manifold), tank size, and fluid type. Aqueous solutions do not require the same level of chemical compatibility as solvents and strong acids.

Considerations for choosing the optimal pump include:

- flow rate proportional to the volume of the system

- oil-free operation with excellent chemical compatibility

- adjustable control of vacuum levels

- solvent recovery options in both inlet and outlet

The pumps available:

→ Laboport N 96 - flow rate 7 l/min, final vacuum 130 mbar and IP40

→ Laboport N 816.3 KT.18 - flow rate 16 l / min, final vacuum 20 mbar and IP20

→ Laboport N 816.1.2 KT.18 - flow rate 30 l / min, final vacuum 160 mbar and IP20

→ Laboport N 820 G - Flow rate 20 l/min, max vacuum 6 mbar and IP30

→ Laboport N 840 G - Flow rate 34 l/min, max vacuum 6 mbar and IP30

→ Laboport N 840.3 FT.18 - flow rate 34 l / min, final vacuum 8 mbar and IP44

→ Laboport N 938.50 KT.18 - flow rate 30 l/min, final vacuum 15mmbar and IP20

SUCTION OF FLUIDS

During the aspiration of a liquid you have: a container for liquids, a tube, a collection bottle and a vacuum pump. Often a filter is placed on the inlet side of the pump to prevent liquid from being sucked in.

This process is relatively simple and the ideal vacuum pump should have:

- oil-free operation with excellent chemical compatibility

- adjustable flow rate

- levels of flow and vacuum appropriate for the application

The pumps available:

→ Laboport N 96 - flow rate 7 l/min, final vacuum 130 mbar and IP40

→ N 86 KT.18 - Small, economical and suitable for almost all uses; flow rate 5,5 l/min and final vacuum 160 mbar

→ Laboport N 816.3 KT.18 - flow rate 16 l / min, final vacuum 20 mbar and IP20

→ Laboport N 816.1.2 KT.18 - flow rate 30 l / min, final vacuum 160 mbar and IP20

→ Laboport N 820 G - Flow rate 20 l/min, max vacuum 6 mbar and IP30

→ Laboport SR 820 G - Flow rate 20 l / min, max vacuum 6 mbar and IP30

→ Laboport SR 840 G - Flow rate 34 l / min, max vacuum 6 mbar and IP30

The simplicity of use of the control panel of the SIMDOS model, for dosing liquids.

TRANSFER OF LIQIDS

Liquid transfer can occur for several reasons in a laboratory. Regardless of the application, Liquiport® liquid transfer pumps offer a safe and reliable way to transfer fluids. A simple and intuitive control knob allows you to select the desired range. The RC version offers remote control, allowing you to maintain a safe distance with liquids.

As with all KNF diaphragm pumps for liquids, various head materials are available so that you can select the best possible pump for the fluid you will be using. Also, there is no tube compression, which means pump performance will not vary over time.

An optimal pump includes:

- selection of the desired transfer speed

- oil-free operation with excellent chemical compatibility

- range of control options

The pumps available:

→ Liquiport NF 1.100 S - flow rate 0.2-1.3 l / min, final vacuum 4 mbar and IP65

→ Liquiport NF 100 S - flow rate 0.2-1.3 l / min, final vacuum 1 mbar and IP65

→ Liquiport NF 1.300 S - flow rate 0.5 - 3.0 ml / min, final vacuum 4 mbar and IP65

→ Liquiport NF 300 S - flow rate 0.5 - 3.0 ml / min, final vacuum 1 mbar and IP65

By dosage:

→ Simdos 02 FEM 1.02 KT 18 S - flow rate 0.03-20 ml / min, final vacuum 6 mbar and IP65

→ Simdos 10 FEM 1.10 KT.18 S- flow rate 1-100 ml / min, final vacuum 6 mbar and IP65

DRYING

Drying is a process that aims to remove water from a solid or to maintain a dry environment for moisture-sensitive materials.

A vacuum dryer connects to a laboratory vacuum pump which removes moisture and air from the chamber. It is particularly suitable for materials that require dust-free and completely dry storage. The dryer is equipped with a connection port for the pump, which is designed to withstand the depth of vacuum generated by the pump.

The ideal pump for such applications must:

- operate oil-free with excellent chemical compatibility

- be able to process humid vapors

- have the maximum vacuum depth

- have a flow rate proportional to the volume of the system

The pumps available:

→ Laboport N 816.3 KT.18 - flow rate 16 l / min, final vacuum 20 mbar and IP20

→ Laboport N 816.1.2 KT.18 - flow rate 30 l / min, final vacuum 160 mbar and IP20

→ Laboport N 820 G - flow rate 20 l/min, max vacuum 6 mbar and IP30

→ Laboport N 840 G - flow rate 34 l/min, max vacuum 6 mbar and IP30

→ N 920 KT.29.18 G - flow rate 21 l/min, max vacuum 2 mbar and IP20

→ Laboport N 938.50 KT.18 - flow rate 30 l/min, final vacuum 15mmbar and IP20

GEL DRYING

Gel dryers are a tool for preparing electrophoresis gels used in laboratories for DNA, RNA and protein analysis.

Applying a controlled vacuum ensures that the gel is completely dry minimizing the risk of gel breakage.

The ideal pumps are:

- flow / vacuum levels appropriate for the apparatus and the medium

- oil-free operation with excellent chemical compatibility

- adjustable control of vacuum levels

- solvent recovery options in both inlet and outlet

The pumps available:

→ Laboport N 820 G - flow rate 20 l/min, max vacuum 6 mbar and IP30

→ Laboport N 840 G - flow rate 34 l/min, max vacuum 6 mbar and IP30

→ N 920 KT.29.18 G - flow rate 21 l/min, max vacuum 2 mbar and IP20

→ Laboport N 820.3 FT.18 - flow rate 20 l / min, final vacuum 8 mbar and IP44

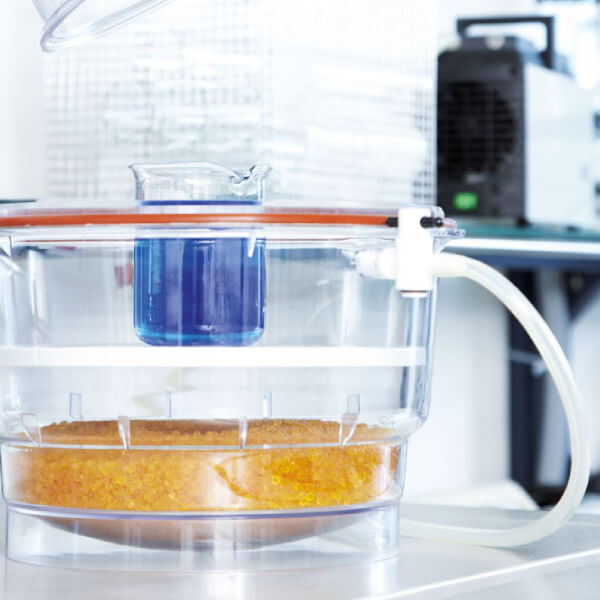

SPE - EXTRACTION IN THE SOLID PHASE

Solid phase extraction (SPE) is a technique designed for rapid and selective sample preparation and purification prior to chromatographic analysis (eg HPLC, GC, TLC). The compounds are dissolved in a liquid and separated according to their chemical and physical properties.

SPE is used in food and beverage manufacturing, water treatment, soil analysis, environmental applications, separation science, pharmaceuticals, and clinical chemistry.

The ideal vacuum pump for this application is equipped with:

- flow / vacuum levels suitable for the volume of the SPE apparatus

- oil-free operation with excellent chemical compatibility

- adjustable control of vacuum levels

- ability to process humid vapors

- outlet condenser for solvent recovery

The pumps available:

→ Laboport N 96 - flow rate 7 l/min, final vacuum 130 mbar and IP40

→ N 86 KT.18 - flow rate 5,5 l/min and final vacuum 160 mbar→ Laboport N 816.3 KT.18 - flow rate 16 l/min, final vacuum 20 mbar and IP20

→ Laboport N 938.50 KT.18 - flow rate 30 l/min, final vacuum 15mmbar and IP20

If you are interested in laboratory ovens we offer you POL-EKO ovens.

FOR VACUUM OVENS

Vacuum ovens effectively remove moisture from a substance through the combined effects of high temperature and low pressure. As the pressure around the substance is reduced, more evaporation will occur at lower temperatures. When drying is done at higher temperatures, lowering the pressure will allow for faster evaporation.

The vacuum oven controls the temperature, while the vacuum pump reduces the pressure inside the oven chamber. This application can be used in the pharmaceutical, textile, paper, ceramic and rubber industries. Furthermore, vacuum ovens are part of an important process for removing solvents from botanical extractions.

The pump for vacuum ovens are equipped with:

- oil-free operation with excellent chemical compatibility

- vacuum control options

- ability to process humid vapors

The pumps available:

→ Laboport N 820 G - flow rate 20 l/min, max vacuum 6 mbar and IP30

→ Laboport N 840 G - flow rate 34 l/min, max vacuum 6 mbar and IP30

→ Laboport N 842.3 KT.18 - flow rate 34 l/min, max vacuum 2 mbar and IP44

→ Laboport N 820.3 FT.40.18 - flow rate 20 l / min and final vacuum 10 mbar

→ Laboport N 840.3 FT.40.18 - flow rate 34 l / min and final vacuum 10 mbar

→ Laboport N 860.3 FT.40.18 - flow rate 60 l / min and final vacuum 4 mbar

→ Laboport SR 820 G - flow rate 20 l / min, max vacuum 6 mbar and IP30

→ Laboport SR 840 G - flow rate 34 l / min, max vacuum 6 mbar and IP30

→ New! Laboport SC 820 G - Flow rate 20 l / min, max vacuum 6 mbar and IP30

→ New! Laboport SC 840 G - Flow rate 34 l / min, max vacuum 6 mbar and IP30

Not enough for you? Do you want to go into detail about KNF pumps and their advantages? Listen directly to the KNF experts in the video opposite: 'Vacuum pumps - an underrated tool in the laboratory'

In the video 3 examples of laboratory applications and how the new LABOPORTs make your daily routine efficient and precise. You will discover all the features of the new LABOPORT design, their use and their advantages.

Federico Ellade Peruzzotti

In Jointlab since 2013 as a creator of texts and graphics.

.jpg)

(1).jpg)

(1).jpg)